Top Microcontroller Power Management Techniques for Hobbyists

Category: Embedded Systems

Unlock Efficient Power Management in Your Microcontroller Projects

If you’re a tech enthusiast, developer, or hobbyist diving into the world of Raspberry Pi and microcontroller applications, power management is crucial. Maybe you’ve started a cool embedded project but noticed your device drains batteries fast or overheats quickly under continuous operation. That’s where mastering microcontroller power management techniques becomes a game-changer. This post cuts through overwhelming technical jargon to deliver practical, effective strategies to optimize power use without sacrificing performance. From hardware tweaks to software-level controls like sleep modes and dynamic frequency scaling, we’ll explore actionable solutions tailored for Python, C/C++, and embedded systems development. Whether you're building remote sensors, wearables, or automation tools, learning how to extend battery life and reduce energy waste will amplify your project’s reliability and usability. You found this article because you care about creating smart, efficient devices that run longer and smarter. We're here to walk you through the best practices backed by modern designs and real-world applications, so you can implement them quickly in your next build. Dive in to transform how you design your microcontroller-powered creations!

- Unlock Efficient Power Management in Your Microcontroller Projects

- Understanding Power Consumption in Microcontrollers: Key Components and Typical Power Profiles

- Hardware Strategies for Power Efficiency: Choosing the Right Microcontroller and Components

- Utilizing Sleep and Low-Power Modes: Maximizing Energy Savings in Your Microcontroller Projects

- Dynamic Voltage and Frequency Scaling (DVFS): Balancing Performance and Power in Real-Time

- Power-Efficient Software Design Practices: Writing Interrupt-Driven Code and Optimizing CPU and Peripheral Usage

- Energy Harvesting and Battery Management: Techniques to Extend Device Runtime

- Monitoring and Profiling Power Usage: Tools and Methods for Measuring Consumption on Development Boards and Final Products

- Case Studies in Microcontroller Power Management: Real-World Examples Using Raspberry Pi Pico, STM32, and Arduino Platforms

- Advanced Topics: Using DMA to Reduce CPU Load, Peripheral Clock Gating, and Optimizing Wake-Up Sources

- Best Practices and Common Pitfalls: Ensuring Sustainable Low-Power Microcontroller Designs

Understanding Power Consumption in Microcontrollers: Key Components and Typical Power Profiles

Before diving into power management techniques, it’s essential to understand where and how microcontrollers consume power in embedded systems. Microcontroller power consumption typically depends on several key components and operational modes that define the device’s energy profile. At a high level, the main contributors to power usage include:

-

Core CPU Activity: The heart of any microcontroller is its CPU core, which consumes the most energy during active processing. Power draw scales with clock speed and workload complexity — higher frequencies and intensive computations lead to increased current consumption.

-

Peripherals and Interfaces: Integrated modules such as ADCs, UARTs, SPI, I2C, timers, and communication radios add to the power budget. Some peripherals draw considerable power even while idle, making selective activation critical.

-

Memory Subsystems: Flash, SRAM, and EEPROM modules require power for data access and retention. The power profile varies between read/write cycles and idle states.

-

Clock Systems: The oscillators and PLLs (phase-locked loops) that generate timing signals are constant consumers, with high-frequency clocks typically using more energy.

-

Power Regulators and External Components: Voltage regulators and any connected sensors or actuators impact overall consumption.

Typical power profiles of embedded devices fluctuate between active, idle, sleep, and deep sleep modes, each offering a trade-off between responsiveness and energy efficiency. For example, in active mode, microcontrollers may draw tens of milliamps, whereas in deep sleep, consumption can drop to microamps. Understanding these profiles is crucial for crafting effective power management strategies that extend battery life and maintain system performance.

By breaking down power consumption into these core areas, you gain insights into where optimization efforts yield the highest returns — whether through clock scaling, peripheral gating, or leveraging low-power sleep states offered by modern microcontrollers. This foundational knowledge sets the stage for implementing techniques that minimize energy footprints in your Raspberry Pi and other microcontroller projects.

Image courtesy of Pok Rie

Hardware Strategies for Power Efficiency: Choosing the Right Microcontroller and Components

Optimizing your embedded project’s power consumption starts with selecting hardware components deliberately tailored for low power operation. The choice of microcontroller, voltage regulators, and hardware peripherals directly impacts energy efficiency and battery life, often more profoundly than software tweaks alone.

Selecting Low Power Microcontrollers

When aiming for power efficiency, prioritize microcontrollers (MCUs) designed specifically for low power applications. Key features to look for include:

- Ultra-Low Power Modes: MCUs that support multiple sleep states—such as deep sleep, stop, or standby modes—allow dramatic power savings by shutting down unused modules and reducing clock rates.

- Dynamic Frequency Scaling: The ability to adjust CPU clock speeds on the fly helps balance performance versus energy use.

- Integrated Voltage Scaling: Some MCUs can dynamically adjust their internal core voltage based on workload, minimizing power draw.

- Efficient Peripherals: Select MCUs with low energy peripheral modules (e.g., low-power ADCs, DMA controllers) that can operate autonomously without waking the core.

Popular power-efficient microcontrollers include the ARM Cortex-M0+ based chips (e.g., from Nordic Semiconductor, STM32L series), and the Atmel SAM L series, all boasting sleep currents as low as single microamps.

Using Efficient Voltage Regulators

Voltage regulation is often an overlooked area where power is wasted. Choosing the right regulator ensures your microcontroller and peripherals receive stable voltages without excessive energy loss:

- Low-Dropout Regulators (LDOs): Ideal for minor voltage drops with low quiescent currents, suitable for moderate efficiency needs.

- Switching Regulators (Buck or Boost Converters): Offer much higher efficiency when stepping voltage down or up, though they require careful consideration of switching noise.

- Integrated DC-DC Converters: Some microcontrollers include built-in switching regulators, reducing external components and improving overall power efficiency.

Selecting and Managing Hardware Peripherals

Many embedded projects integrate sensors, communication modules, and actuators, each adding to power consumption. To maximize efficiency:

- Opt for low power or ultra-low power peripheral components certified for sleep or standby modes.

- Use peripherals with hardware interrupts or DMA support to minimize active CPU time.

- Physically disconnect or power down unused peripherals via hardware switches or software-controlled power domains.

By combining a carefully selected low power MCU, efficient voltage regulation, and judicious peripheral management, you establish a solid hardware foundation for extended battery life and minimal energy waste. These hardware-centric strategies form the backbone for more advanced firmware power optimizations like sleep management and peripheral gating, which we'll explore next.

Image courtesy of Pok Rie

Utilizing Sleep and Low-Power Modes: Maximizing Energy Savings in Your Microcontroller Projects

One of the most effective techniques to reduce power consumption in microcontroller-based systems is to leverage sleep and low-power modes. Modern microcontrollers offer a variety of configurable states—such as sleep, deep sleep, standby, and stop modes—that strategically disable or scale down CPU activity and peripheral functions while maintaining essential system responsiveness. Proper use of these modes can lower power consumption from milliamps during active operation to mere microamps during inactivity, drastically extending battery life in portable or remote projects.

Overview of Common Sleep States

- Sleep Mode: The CPU halts execution, but peripherals and clocks can remain active, allowing for fast wake-up times. This mode suits brief idle periods where responsiveness is critical.

- Deep Sleep / Stop Mode: Both CPU and most peripheral clocks are stopped, with only select wakeup sources (like real-time clocks or external interrupts) kept operational. Deep sleep achieves significantly lower power draw with longer wakeup latency.

- Standby Mode: The microcontroller enters its lowest power consumption state by powering down almost all internal circuits except a small part of the power management unit. Typically, standby mode maintains memory contents but requires explicit wakeup signals, making it ideal for extended inactivity.

- Power-Down Mode: Some MCUs offer an even more aggressive power saving mode where RAM may lose its contents, and the device essentially resets upon wakeup.

Configuring Sleep States for Efficient Power Management

To implement these low-power modes effectively:

- Identify appropriate wakeup sources such as GPIO interrupts, timers, or communication events that should bring the device out of sleep.

- Use MCU-specific registers and APIs to enable and configure the desired sleep state, ensuring that unnecessary clocks and peripherals are disabled during sleep.

- Preserve critical data and system state before entering deep sleep or standby, so the device can resume operation seamlessly after waking.

- Carefully manage wake-up latency versus power savings trade-offs, selecting lighter sleep modes for frequent wakeups and deeper modes for long idle periods.

Many development frameworks and SDKs, including those for ARM Cortex-M and popular microcontrollers like STM32 or ESP32, provide built-in functions or drivers to simplify sleep mode activation and configuration. For example, in ARM Cortex-M systems, the WFI (Wait For Interrupt) or WFE (Wait For Event) assembly instructions trigger sleep modes efficiently, often wrapped by higher-level API calls in C/C++ or Python libraries.

By strategically incorporating these sleep and low-power modes into your embedded firmware, you can achieve dramatic reductions in energy consumption without sacrificing system responsiveness or functionality—a foundational step toward truly efficient microcontroller projects optimized for battery life and sustainability.

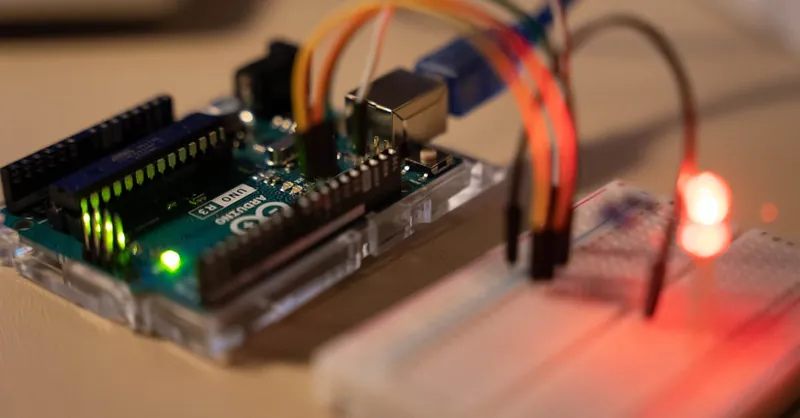

Image courtesy of Pixabay

Dynamic Voltage and Frequency Scaling (DVFS): Balancing Performance and Power in Real-Time

One of the most powerful techniques for conserving energy without compromising microcontroller performance is Dynamic Voltage and Frequency Scaling (DVFS). DVFS involves adjusting the microcontroller’s clock speed and core voltage on-the-fly, based on the current workload and processing demands. By scaling down both the frequency and voltage during periods of low activity, DVFS drastically reduces power consumption since power dissipation in CMOS circuits is proportional to the square of the voltage and linearly proportional to the frequency.

How DVFS Works in Practice

- Real-Time Clock Speed Adjustment: When the microcontroller detects reduced computational requirements—such as waiting for sensor data or a communication response—it lowers its CPU clock frequency. This reduces the switching activity inside the chip, saving power.

- Dynamic Voltage Reduction: Lower CPU frequencies allow the core voltage to be reduced safely without compromising signal integrity or timing. This voltage scaling further reduces current consumption exponentially.

- Workload Monitoring: Embedded firmware or operating systems running on the microcontroller continuously monitor system workload to decide when to increase or decrease frequency and voltage, enabling seamless transitions between high performance and energy-saving states.

Key Benefits of DVFS for Embedded Systems

- Extended Battery Life: By lowering voltage and clock speed during idle or low-demand periods, DVFS minimizes wasted energy, enabling longer operation on limited power budgets common in IoT devices, wearables, and remote sensors.

- Reduced Heat Generation: Running at adequate but lower power levels reduces heat dissipation, enhancing device reliability and eliminating the need for bulky cooling solutions.

- Maintained Responsiveness: Unlike static power savings that often trade responsiveness for energy, DVFS adapts dynamically and swiftly, ensuring the microcontroller runs only as fast and as power-hungry as necessary at any moment.

Implementing DVFS on Popular Microcontrollers

Many modern microcontrollers inherently support DVFS or related features like clock gating and programmable voltage regulators. For example:

- ARM Cortex-M based MCUs can adjust clock frequencies via clock control registers and support voltage scaling with integrated power management units.

- ESP32 and similar SoCs provide APIs to configure CPU frequency dynamically through registers accessible in C/C++ or MicroPython firmware.

- Vendors like STMicroelectronics (STM32L series) and Nordic Semiconductor (nRF52) offer built-in DVFS capabilities through their driver libraries, easing integration.

To harness DVFS in your embedded projects:

- Profile your application's computational needs to identify typical idle and active periods.

- Use firmware constructs such as timers, interrupts, or RTOS hooks to trigger frequency and voltage scaling events.

- Carefully verify voltage-frequency operating points to avoid unstable MCU behavior, leveraging datasheets and manufacturer application notes.

By integrating Dynamic Voltage and Frequency Scaling into your power management approach, your microcontroller projects on platforms like Raspberry Pi Pico or STM32 can achieve optimal energy efficiency paired with excellent performance, ensuring smarter and longer-lasting embedded solutions.

Image courtesy of Pixabay

Power-Efficient Software Design Practices: Writing Interrupt-Driven Code and Optimizing CPU and Peripheral Usage

Achieving maximum power efficiency in microcontroller projects extends far beyond hardware selection—it requires deliberate and optimized software design. Key to this effort is embracing interrupt-driven programming, minimizing active CPU time, and optimizing peripheral usage to reduce unnecessary energy consumption.

Writing Interrupt-Driven Code

Traditional polling loops continuously check status flags and sensor inputs, unnecessarily keeping the CPU active and consuming power. By contrast, interrupt-driven code allows the microcontroller to enter low-power sleep states and wake only when specific events occur, such as sensor input, communication packets, or timer expirations. This approach ensures:

- Minimal Active CPU Time: The CPU runs only when processing is truly needed, otherwise remaining idle or asleep to conserve energy.

- Faster Response with Lower Overhead: Interrupt service routines (ISRs) efficiently handle real-time events without the latency and waste associated with constant polling.

- Improved Peripheral Autonomy: Many peripherals can generate interrupts on their own (e.g., ADC conversion complete, UART RX ready), enabling asynchronous operation without CPU intervention.

To implement interrupt-driven design effectively:

- Configure peripheral interrupts precisely, enabling only necessary sources.

- Keep ISRs short and efficient, deferring complex processing to main loops if possible.

- Clear interrupt flags appropriately to prevent repeated wake-ups.

Minimizing Active CPU Time

Even with interrupts, minimizing the time the CPU spends active is critical. Strategies include:

- Offload tasks to hardware peripherals: Utilize DMA controllers, timers, and communication modules to handle data transfers or timing autonomously, reducing CPU cycles.

- Batch processing: Accumulate sensor data or events and process them in fewer, consolidated bursts rather than continuous handling.

- Optimize algorithms and code paths: Profile and streamline code to reduce execution time, especially in critical loops, further reducing power usage.

Optimizing Peripheral Usage

Peripheral modules can remain significant power consumers if left enabled unnecessarily. To optimize peripheral energy use:

- Enable peripherals only when required, disabling or powering down unused modules immediately after their tasks complete.

- Leverage low-power peripheral modes: Many MCUs support reduced-power operation of peripherals that can function independently (e.g., low-power ADC sampling, watchdog timers).

- Use proper clock gating: Ensure peripheral clocks are stopped when hardware modules are inactive, as idle peripherals still consume dynamic power.

By combining interrupt-driven programming, minimizing active CPU runtime, and careful peripheral management, embedded software plays a pivotal role in reducing overall power consumption. These practices complement hardware power-saving features and enable your microcontroller projects—whether on Raspberry Pi Pico, STM32, or other platforms—to operate longer and more efficiently under tight energy budgets.

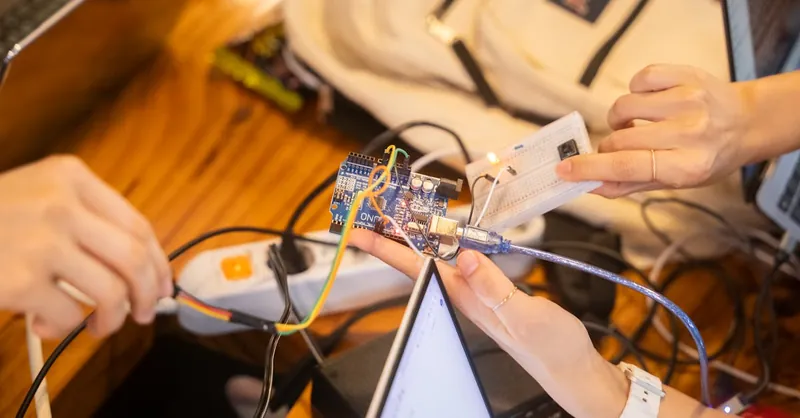

Image courtesy of Youn Seung Jin

Energy Harvesting and Battery Management: Techniques to Extend Device Runtime

Maximizing the runtime of your microcontroller projects doesn't rely solely on reducing power consumption—it also involves capturing ambient energy and optimizing battery usage. Integrating energy harvesting techniques such as solar or motion-based power sources, combined with sophisticated battery management circuits, can significantly extend operational life and reduce maintenance for battery-powered embedded systems.

Harnessing Renewable Energy Sources for Microcontrollers

In applications like remote sensors, wearables, or IoT nodes, intermittent or continuous ambient energy can be harvested to supplement or replace traditional batteries. Popular energy harvesting methods include:

- Solar Energy: Lightweight, compact photovoltaic (PV) cells convert sunlight into electrical energy. Solar harvesters can charge batteries or supercapacitors during the day, enabling devices to run indefinitely with minimal user intervention.

- Motion and Vibration: Piezoelectric elements or electromagnetic harvesters generate power from physical motion or vibrations, ideal for wearable projects or machinery monitoring systems.

- Thermal Gradients: Thermoelectric generators convert heat differences into electrical energy, useful in industrial or environmental monitoring where temperature gradients exist.

When designing for energy harvesting:

- Select energy sources appropriate to the environment and application.

- Use power conditioning circuits like low-loss rectifiers, maximum power point tracking (MPPT) controllers, and DC-DC converters to efficiently capture and transfer harvested energy.

Optimizing Battery Charging and Management Circuits

Efficient battery management is critical to prolong battery life, ensure safety, and enable reliable operation:

- Smart Charging Controllers: Employ integrated circuits that handle charging profiles specific to battery chemistry (Li-ion, NiMH, etc.), including constant current and constant voltage phases.

- Battery Fuel Gauges: Monitor battery voltage, current, and temperature to provide accurate state-of-charge data, preventing over-discharge or overcharge conditions.

- Power Path Management: Allow simultaneous powering of the device and charging of the battery, maintaining uninterrupted operation even during energy harvesting fluctuations.

Additionally, consider hardware and firmware techniques such as:

- Implementing low quiescent current power controllers to minimize self-discharge in idle periods.

- Utilizing battery balancing circuits for multi-cell packs to maintain long-term capacity.

- Designing firmware to switch loads or scale performance dynamically based on available energy and battery status.

By combining energy harvesting with advanced battery management, your embedded systems can achieve near-perpetual operation and higher resilience—especially in off-grid, mobile, or hard-to-access deployments. This approach not only improves power autonomy but also aligns with sustainable, green technology trends increasingly important in modern microcontroller projects.

Image courtesy of Kindel Media

Monitoring and Profiling Power Usage: Tools and Methods for Measuring Consumption on Development Boards and Final Products

Accurate power monitoring and profiling are critical steps for fine-tuning microcontroller power management strategies and validating real-world energy savings in your embedded projects. Whether you are optimizing a Raspberry Pi Pico-based sensor node or a complex STM32 system, quantifying how much current your device consumes during different operating modes—active processing, sleep states, or peripheral operation—enables targeted improvements and informed design decisions.

Essential Tools for Power Measurement

-

Multimeters and Oscilloscopes:

For simple current measurements, a high-precision multimeter can provide instant current or voltage readings. Oscilloscopes with current probes offer more detailed insights into transient power spikes and switching behaviors during specific code execution phases or peripheral activity. -

Precision Current Sensors:

Low-resistance shunt resistors combined with amplifiers (e.g., INA219, ACS712) allow real-time current monitoring with microamp sensitivity. These sensors can be integrated into debug setups or even included in final products to enable continuous power profiling and feedback. -

Dedicated Power Analyzers:

Instruments such as the Monsoon Power Monitor, Otii Arc, or Keysight N6705C provide high-resolution current and voltage logging with timestamped data. These tools support programmable triggers and scripting, allowing in-depth analysis of power consumption linked to specific firmware events. -

On-Board Monitoring Features:

Many modern microcontrollers and development platforms include integrated analog-to-digital converters (ADCs) or built-in current monitors to sample supply currents or voltage drops. Coupling this with firmware support offers a lightweight approach to estimate power with minimal external hardware.

Best Practices for Effective Power Profiling

- Measure Across All Operating Modes: Profile power not only during active computation but also during sleep, idle, and peripheral-driven intervals to identify unexpected drains or misconfigurations.

- Use Breakpoints and Logging to Correlate Power and Code Execution: Combining power traces with software debugging reveals which parts of your code cause power spikes or prolonged active states.

- Test Under Realistic Conditions: Include all relevant components—sensors, radios, actuators—powered and interacting as in the final application to capture the full system power profile.

- Automate and Repeat Measurements: Whenever possible, automate power profiling with scripts or integrated tools to gather statistically significant data and track improvements as you optimize firmware and hardware.

By rigorously monitoring and profiling power consumption, you gain critical insights into the actual energy behavior of your microcontroller projects. This information is indispensable for validating the effectiveness of hardware selections, sleep mode configurations, and DVFS implementations. Ultimately, precise power measurement empowers you to deliver smarter, longer-lasting, and energy-efficient embedded systems tailored for both development and deployment phases.

Image courtesy of Fatih Yurtman

Case Studies in Microcontroller Power Management: Real-World Examples Using Raspberry Pi Pico, STM32, and Arduino Platforms

To illustrate how effective microcontroller power management techniques translate into real-world applications, let’s explore practical case studies leveraging popular embedded platforms like the Raspberry Pi Pico, STM32 series, and Arduino boards. These examples highlight tailored strategies combining hardware and software optimizations to maximize battery life and energy efficiency in diverse project scenarios.

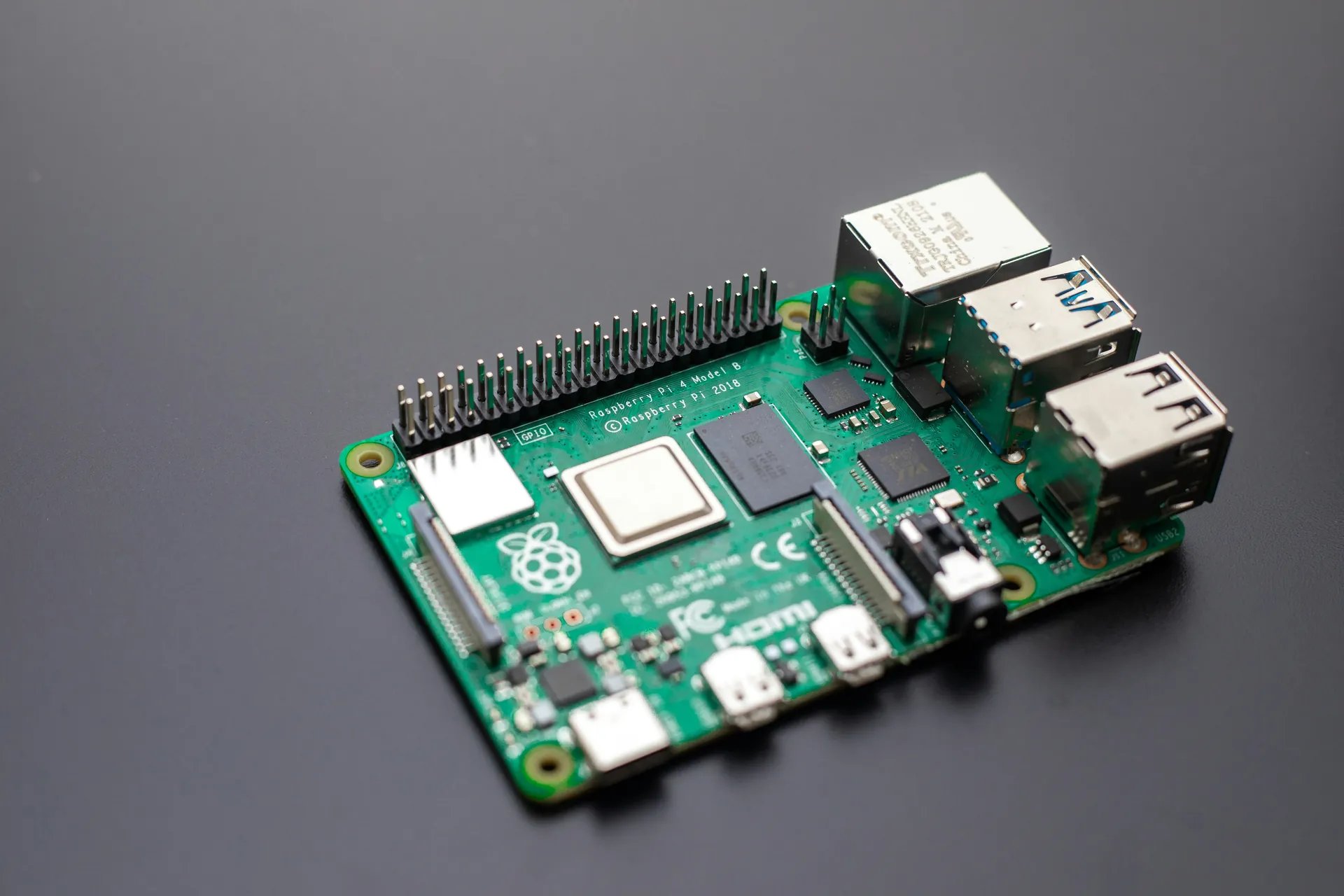

Raspberry Pi Pico: Ultra-Low Power Sensor Node

The Raspberry Pi Pico, based on the RP2040 microcontroller, offers robust power management options suitable for battery-powered IoT devices. In a remote environmental sensor project, developers implemented the following power-saving measures:

- Sleep Mode Utilization: By putting the RP2040 into dormant mode during idle periods, the project reduced current draw from active levels of around 12mA down to less than 1mA.

- Peripheral Management: Sensors and communication modules (e.g., I2C humidity sensors, LoRa radios) were selectively powered off or placed into low-power standby when not sampling or transmitting.

- Interrupt-Driven Wakeup: GPIO interrupts alerted the microcontroller for immediate sensor readings or data transmission, minimizing wake time.

- Dynamic Frequency Scaling: Firmware adjusted the clock frequency dynamically between 48MHz during processing bursts and 12MHz during lower-demand intervals, trimming power consumption without sacrificing responsiveness.

This combination enabled the sensor node to operate on a small LiPo battery for months, demonstrating how leveraging RP2040’s power modes and scalability dramatically extends embedded device longevity.

STM32 Microcontrollers: Wearable Fitness Tracker

STM32 MCUs, such as the STM32L4 series, are widely recognized for their comprehensive low-power features, making them ideal for wearable devices. In a fitness tracker project, engineers applied:

- Deep Sleep and Stop Modes: The firmware transitioned the device into deep sleep when the user was inactive or during screen-off periods, reducing current consumption to microamp levels.

- Peripheral Autonomous Operation: The built-in RTC and accelerometer were configured to function independently, waking the MCU only when motion or timed events occurred.

- DVFS Implementation: The CPU clock frequency was dynamically adjusted based on workload, optimizing energy usage during computationally intensive tasks such as activity recognition.

- Battery Fuel Gauge Integration: Continuous monitoring of battery state allowed adaptive power budgeting and user notifications for charging needs.

These design choices enabled the fitness tracker to deliver a multi-day runtime without bulky batteries, highlighting STM32’s powerful low-power modes and peripheral flexibility in real-world embedded health applications.

Arduino Platform: Off-Grid Data Logger

Arduino boards, especially those based on ATmega328P like the Arduino Uno or Pro Mini, remain popular for quick prototyping of low-power projects. In a solar-powered off-grid data logger, effective power management practices included:

- Sleep Mode with Watchdog Timer: The ATmega328P was placed into the Power-Down sleep mode and periodically awakened through the watchdog timer to take sensor measurements, dropping average current consumption to around 15µA.

- Selective Peripheral Shutdown: Unused modules such as the ADC or UART were disabled in software during sleep intervals.

- Energy Harvesting Integration: A small solar panel charged a rechargeable battery during daylight, supplemented by smart firmware to suspend operations under low battery conditions.

- Minimalist Firmware Design: The code was optimized for minimal wake time and efficient sensor reads, reducing active CPU cycles.

This setup allowed continuous, maintenance-free data collection in remote locations for weeks, demonstrating how classic Arduino microcontrollers, combined with foundational power-saving techniques, remain highly effective in energy-constrained environments.

These practical case studies showcase how leveraging hardware capabilities, sleep management, dynamic frequency scaling, and energy harvesting across Raspberry Pi Pico, STM32, and Arduino platforms can significantly reduce power consumption in embedded projects. By adopting similar strategies tailored to your specific microcontroller and application needs, you can design smarter, longer-lasting devices that excel in field deployments and battery-powered scenarios.

Image courtesy of Chengxin Zhao

Advanced Topics: Using DMA to Reduce CPU Load, Peripheral Clock Gating, and Optimizing Wake-Up Sources

To unlock next-level power efficiency in your microcontroller projects, it’s essential to explore advanced firmware and hardware techniques that minimize active CPU usage and streamline peripheral operations. Three powerful strategies—Direct Memory Access (DMA), peripheral clock gating, and intelligent wake-up source optimization—collectively reduce unnecessary power draw and enhance responsiveness without burdening the processor.

Leveraging DMA to Offload the CPU

Direct Memory Access (DMA) enables peripherals such as ADCs, UARTs, SPI, and I2C controllers to transfer data directly to memory or between memory regions without CPU intervention. By offloading these data movements from the processor, DMA minimizes active CPU cycles and allows the microcontroller to remain in low-power modes longer.

Key benefits of using DMA for power management include:

- Minimized CPU Wake Time: The CPU only wakes to configure or finalize transfers, not for the entire data movement process.

- Reduced Interrupt Overhead: DMA typically generates fewer interrupts compared to polling or peripheral interrupts on each byte or word transferred.

- Lower Power Consumption: Less CPU activity leads directly to reduced dynamic power usage, especially important in high-throughput or sensor-intensive applications.

When implementing DMA:

- Ensure proper buffer management and synchronization between DMA transfers and CPU processing to avoid data corruption.

- Use peripheral features like hardware trigger signals to start DMA transfers automatically, maximizing autonomous operation.

- Consider multi-channel DMA where supported, to handle simultaneous data streams efficiently.

Using Peripheral Clock Gating to Cut Idle Power Draw

Peripheral clock gating is a hardware-level power-saving method that selectively disables the clock signals to unused peripherals, effectively stopping their internal logic from switching and consuming dynamic power. Modern microcontrollers support fine-grained clock gating through control registers, allowing software to:

- Turn off clocks to inactive communication interfaces (e.g., disable SPI when not transferring data).

- Disable timer or ADC clocks when these modules are idle.

- Manage clock domains dynamically, ensuring only active peripherals are clocked.

Implementing clock gating properly requires systematic software control to avoid peripherals operating inadvertently without clocks and to re-enable clocks seamlessly when needed. By reducing clock signals to dormant peripherals, you can achieve significant savings in overall system power consumption.

Optimizing Wake-Up Sources for Efficient Power Cycling

The choice and configuration of wake-up sources dramatically impact how effectively your microcontroller balances power savings and responsiveness. Inefficient wake-up triggers can cause unnecessary power drain by waking the CPU too often or failing to respond timely.

To optimize wake-up sources:

- Use low-power peripherals and sensors capable of generating interrupts without waking the CPU unnecessarily, such as dedicated wake-up pins or low-power comparators.

- Prioritize interrupts from essential events only (e.g., critical sensor thresholds, communication packets) and mask less important sources while in deep sleep modes.

- Leverage hardware timers or real-time clock alarms to schedule timed wake-ups, reducing continuous active polling in software.

- Configure edge- or level-triggered interrupts appropriately to prevent missed or repeated wake-up events.

Proper wake-up source management ensures that your microcontroller spends maximum time in the lowest power states without compromising responsiveness or system reliability.

By integrating DMA-driven data handling, peripheral clock gating, and optimized wake-up configurations, your embedded projects on platforms like Raspberry Pi Pico, STM32, or Arduino can achieve dramatic reductions in power consumption. These advanced techniques complement traditional sleep modes and voltage scaling methods to deliver efficient, high-performance microcontroller applications perfectly suited for IoT, wearables, and battery-powered embedded systems.

Image courtesy of cyber2120

Best Practices and Common Pitfalls: Ensuring Sustainable Low-Power Microcontroller Designs

Achieving sustainable low-power microcontroller designs requires a strategic blend of hardware choices, software optimization, and thorough testing. To maximize battery life and system reliability while avoiding common mistakes, follow these essential best practices:

Key Best Practices for Low-Power Embedded Systems

-

Start with the Right Hardware

Selecting microcontrollers with robust low-power features—such as multiple sleep modes, dynamic voltage scaling, and efficient peripherals—is foundational. Complement your MCU choice with low-quiescent-current regulators and energy-efficient sensors to build a power-savvy hardware platform. -

Design Firmware Around Sleep and Event-Driven Operation

Prioritize interrupt-driven programming to minimize active CPU time. Use deep sleep or standby modes during idle periods and wake only on well-defined events. Integrate power-down sequences that gracefully disable peripherals and clocks that aren’t needed. -

Implement Dynamic Frequency and Voltage Scaling

Utilize DVFS techniques to balance performance demands with energy efficiency dynamically. Scale down clock speeds and voltages during light workloads while ensuring stable operation within MCU specifications. -

Profile and Monitor Power Consumption Continuously

Use precise current measurement tools and onboard monitoring features during development to identify unexpected power drains. Power profiling enables informed optimizations and verifies that firmware and hardware configurations achieve desired savings. -

Incorporate Energy Harvesting and Smarter Battery Management

Where feasible, augment your power strategy with renewable energy sources and intelligent battery management circuits. This reduces dependency on fixed power supplies and extends device uptime in real-world conditions.

Common Pitfalls to Avoid in Low-Power Microcontroller Projects

- Neglecting Peripheral Power Management: Leaving unused peripherals powered or clocks enabled often causes unnecessary current draw. Always disable or gate clocks for inactive modules promptly.

- Overusing Polling Instead of Interrupts: Continuous polling keeps the CPU active and wastes energy. Transition to interrupt-driven designs to maximize sleep time effectiveness.

- Ignoring Wake-Up Source Configuration: Poorly chosen or excessive wake-up sources lead to frequent unintended wake-ups that drain batteries quickly. Carefully select and mask interrupts based on application needs.

- Failing to Validate Power Modes and Transitions: Skipping thorough testing of sleep mode entry/exits or voltage/frequency scaling can cause unstable MCU behavior or lost data, undermining power savings and reliability.

- Overlooking Real-World Conditions in Testing: Laboratory conditions rarely capture all power consumption nuances. Test your system with all components active, under varying environments, and with real user interaction patterns to uncover hidden drains.

By systematically following these best practices and vigilantly avoiding typical power management pitfalls, you ensure your microcontroller projects achieve sustainable, efficient, and reliable operation. This approach not only maximizes battery life but also elevates the overall quality and success of your embedded systems in practical deployments.

Image courtesy of cyber2120