Creating Wearable Devices with Microcontrollers: A Complete Guide

Category: Embedded Systems

Unlock the Potential of Wearable Tech with Microcontrollers

If you're a tech enthusiast, hobbyist, or developer diving into the world of wearable devices, you’ve likely faced the challenge of integrating compact, low-power, and responsive electronics that fit your innovative designs. Whether you’re adept at programming in Python, C/C++, or embedded systems or just starting to explore these skills, this guide will align perfectly with your journey. Finding the right approach to choose microcontrollers, design hardware, and develop efficient firmware for wearables can feel overwhelming amidst the sea of fragmented tutorials and complex datasheets.

This post offers a comprehensive, step-by-step framework covering everything from selecting the best microcontroller platform for wearable projects to optimizing power consumption and integrating sensors and communication modules. Unlike generic guides, we emphasize practical implementation with popular boards like Raspberry Pi and ARM Cortex MCUs, plus language-specific tips for Python and C/C++ development. By reading on, you’ll gain clear insights and actionable knowledge to build wearable devices that truly perform — whether it’s fitness trackers, medical monitors, or smart clothing. Get ready to transform your creative ideas into functional, reliable wearable tech that stands out.

- Unlock the Potential of Wearable Tech with Microcontrollers

- Understanding Wearable Devices

- Choosing the Right Microcontroller for Wearables

- Essential Sensors and Components for Wearable Projects

- Hardware Design and Miniaturization Techniques

- Power Management Strategies for Wearable Devices

- Programming Wearables in Python and C/C++

- Implementing Wireless Connectivity in Wearable Devices

- Developing Firmware for Reliable and Responsive Performance

- Testing, Calibration, and User Interaction in Wearable Devices

- Popular Wearable Projects and Open Source Resources

Understanding Wearable Devices

Wearable devices are compact, portable electronic gadgets designed to be worn on the body, offering continuous interaction or monitoring capabilities. They often combine sensors, microcontrollers, wireless communication modules, and user interfaces into sleek, unobtrusive packages. Wearables come in various forms, including:

- Fitness trackers and smartwatches: Devices that monitor health metrics like heart rate, steps, and sleep patterns.

- Medical monitors: Specialized wearables that track vital signs such as glucose levels, blood pressure, or respiratory rate.

- Smart clothing and accessories: Garments or jewelry embedded with electronics for enhanced functionality or style.

- Augmented Reality (AR) glasses and headsets: Devices that overlay digital information onto real-world views.

When designing wearable devices, several key requirements must be carefully balanced to ensure practical usability and seamless user experience:

- Size and Weight: Wearables must be lightweight and small enough to be comfortable for extended wear without hindering user movement.

- Power Consumption: Battery life is critical—designs should prioritize ultra-low-power microcontrollers and efficient energy management to maximize operational time between charges.

- User Comfort and Ergonomics: Materials, form factor, and device placement should minimize discomfort, skin irritation, and interference with daily activities.

- Durability and Environmental Resistance: Since wearables are exposed to sweat, moisture, and varying temperatures, components and enclosures must withstand these conditions.

Understanding these foundational aspects will guide your selection of microcontrollers, sensors, and communication protocols, helping you create wearable devices that not only function well but also provide reliable, comfortable user experiences.

Image courtesy of Burst

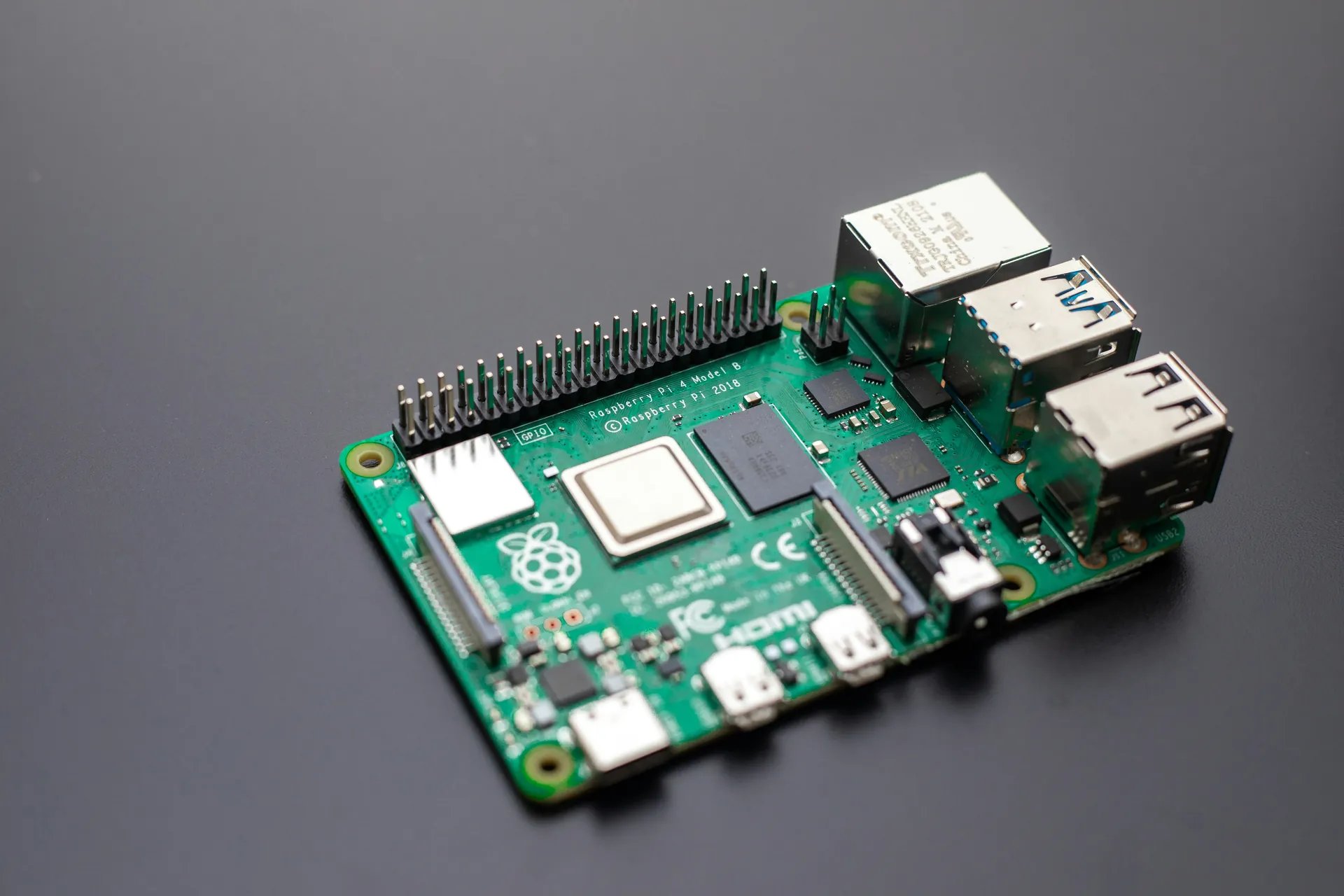

Choosing the Right Microcontroller for Wearables

Selecting the ideal microcontroller (MCU) is a crucial step when designing wearable devices. The chosen MCU directly impacts your project's power efficiency, processing capability, form factor, and connectivity options, all of which determine the success and user experience of your wearable technology. Popular microcontrollers for wearables include low-power ARM Cortex MCUs, ESP32 modules, and the Raspberry Pi Pico, each offering distinct advantages depending on your project needs.

Key Factors to Consider

When evaluating microcontrollers for wearable projects, keep these critical factors in mind:

- Power Consumption: Since wearables rely on small batteries, choose MCUs with ultra-low-power modes to extend battery life without sacrificing responsiveness.

- Processing Power: Balance your application’s computational demands—simple step tracking versus complex signal processing or machine learning will require different MCU capabilities.

- Memory Availability: Adequate RAM and flash memory are vital to support code size, sensor data buffering, and real-time processing.

- Connectivity: Wireless communication such as Bluetooth Low Energy (BLE), Wi-Fi, or proprietary protocols is often needed. Ensure the MCU supports the required connectivity modules or peripherals.

- Form Factor and Integration: Size constraints in wearables necessitate compact MCUs with flexible pinouts and integrated features like ADCs, DACs, and sensor interfaces.

- Development Ecosystem: Availability of SDKs, libraries, and community support can accelerate development and troubleshooting.

Comparing Popular MCUs for Wearables

| Microcontroller | Architecture | Power Consumption | Memory (RAM/Flash) | Connectivity | Programming Languages | Ideal Use Cases |

|---|---|---|---|---|---|---|

| ARM Cortex-M0+/M4 | 32-bit ARM | Ultra low-power modes, ~1-50 mA | 32KB-256KB RAM, up to 1MB Flash | BLE modules via SPI/I2C, some integrate BLE | C/C++, Python (MicroPython) | Fitness trackers, medical sensors |

| ESP32 | Dual-core Xtensa | Moderate (~80-260mA active), deep sleep <10µA | 520KB RAM, 4MB+ Flash | Integrated Wi-Fi, BLE | C/C++, MicroPython, Arduino IDE | Smartwatches, location tracking, IoT wearables |

| Raspberry Pi Pico | dual-core ARM Cortex-M0+ | Very low power (~20-30mA active) | 264KB RAM, 2MB Flash | No native Wi-Fi/BLE (requires external modules) | C/C++, MicroPython | Prototyping, sensor interfacing, custom wearables |

- ARM Cortex-M0+ and M4 MCUs (like those from Nordic Semiconductor or STMicroelectronics) are widely favored for their excellent balance between low power consumption, processing speed, and integrated BLE support, making them well-suited for fitness and health-monitoring devices.

- The ESP32 stands out when your device requires robust wireless communication options (Wi-Fi and BLE) and more powerful processing capabilities, especially for applications involving streaming data or interacting with IoT platforms.

- The Raspberry Pi Pico is an excellent choice for hobbyists and developers familiar with Python or C/C++ who want a versatile, cost-effective microcontroller to prototype wearable sensors or interfaces without native wireless connectivity but with modular expansion options.

By aligning the microcontroller’s capabilities with your wearable application’s power constraints, processing demands, and communication needs, you can ensure your device delivers exceptional performance and battery longevity while maintaining a sleek and comfortable design.

Image courtesy of Thirdman

Essential Sensors and Components for Wearable Projects

Integrating the right sensors and components is pivotal to unlocking the full potential of your wearable device. Selecting and effectively combining sensors such as accelerometers, heart rate monitors, temperature sensors, and others allow your wearable to capture accurate and meaningful data while maintaining low power consumption and compact form factors essential for comfort and usability.

Common Sensors in Wearable Devices

-

Accelerometers and Gyroscopes:

These inertial measurement units (IMUs) detect motion, orientation, and acceleration, fundamental for fitness trackers and gesture recognition. Common chips like the MPU-6050 or LIS3DH offer I2C/SPI interfaces with low power modes, making integration with microcontrollers straightforward. Combined with gyroscopes, they enable more precise motion tracking, tilt detection, and even fall detection. -

Heart Rate Monitors (PPG Sensors):

Photoplethysmography (PPG) sensors use LED light and photodiodes to measure blood volume changes, widely used in smartwatches and health monitors. Modules such as the MAX30100 or MAX30102 provide integrated IR and red LEDs with onboard signal processing, allowing pulse and blood oxygen saturation (SpO2) monitoring. They usually communicate via I2C, making them easy to interface with popular MCUs. -

Temperature Sensors:

Body temperature sensing is crucial for health and environmental monitoring. Digital temperature sensors like the DS18B20 or analog thermistors offer reliable, low-power readings. Placement and calibration are important for accuracy, especially in dynamic wearable environments where skin contact and ambient temperature differ. -

Electrodermal and ECG Sensors:

More specialized sensors like galvanic skin response (GSR) and electrocardiogram (ECG) modules enable stress measurement and cardiac monitoring. Though more complex, integrating these sensors expands wearable capabilities into clinical and wellness applications.

Integration Techniques for Wearable Sensors

- Low-Power Communication Protocols: Most wearable sensors employ I2C or SPI buses for data transfer. Choosing sensors with low-power modes and efficient communication cycles reduces overall energy consumption, critical for battery-operated wearables.

- Sensor Fusion and Data Filtering: Combining data from accelerometers, gyroscopes, and magnetometers using sensor fusion algorithms (e.g., Kalman filtering or complementary filters) enhances accuracy and responsiveness while minimizing noise and false positives.

- Modular Component Selection: Selecting compact, pre-packaged sensor modules with onboard processing or interface circuitry simplifies integration, accelerates development, and reduces required PCB real estate.

- Mechanical and Electrical Considerations: Positioning sensors correctly on the wearable improves measurement accuracy and user comfort. Proper shielding and grounding practices reduce interference, especially in devices with wireless communication.

- Power Management: Use sensor wake-up triggers and sleep modes intelligently—poll sensors only when necessary to conserve power. Employ microcontroller peripherals like timers and interrupts to manage sensor sampling efficiently.

By carefully selecting sensor types suited for your wearable’s target application and integrating them with attention to power, accuracy, and size, you lay the foundation for a functional and user-friendly device. Leveraging widely supported sensor modules ensures compatibility with Raspberry Pi, ARM Cortex MCUs, and popular programming environments like Python and C/C++, streamlining your embedded systems development process for wearables.

Image courtesy of Torsten Dettlaff

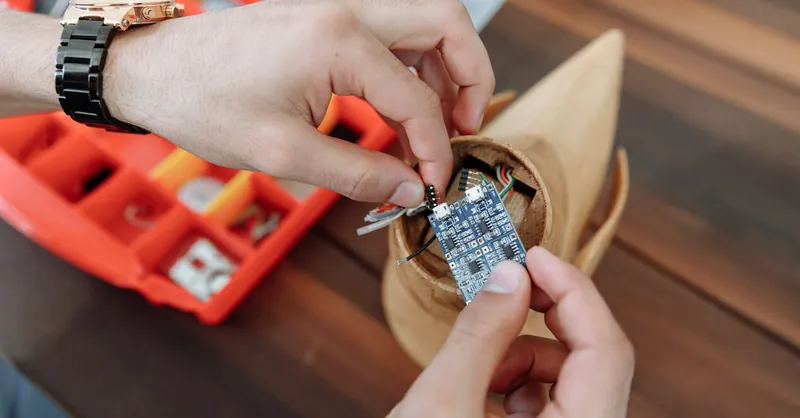

Hardware Design and Miniaturization Techniques

Creating wearable devices demands expertise in compact hardware design to ensure your electronics fit seamlessly into small, ergonomic enclosures without compromising functionality or reliability. Achieving an optimal form factor involves careful PCB layout strategies, flexible circuit technologies, and integrated power management solutions that collectively enhance device durability and user comfort.

PCB Design Tips for Compact Form Factors

Designing a printed circuit board (PCB) for wearables requires maximizing space efficiency while maintaining electrical integrity:

- Use High-Density Interconnect (HDI) Techniques: Employ fine-pitch components, microvias, and multi-layer boards to pack circuits densely without increasing the PCB footprint. HDI allows for shorter signal paths, reducing noise and improving performance in sensitive sensor and wireless modules.

- Optimize Component Placement: Place critical components like microcontrollers and sensors close to each other to minimize trace lengths and electromagnetic interference (EMI). Position connectors and antennas near the PCB edge to facilitate enclosure integration and wireless signal strength.

- Select Small, Low-Profile Components: Choose package types such as QFN, BGA, or CSP for ICs to save space vertically and horizontally. Surface-mount passive components like 0402 or 0201 sizes drastically reduce board area.

- Plan for Thermal Management: Though power consumption is typically low in wearables, localized heat from certain modules (e.g., wireless radios) requires appropriate copper pours and thermal vias to dissipate heat efficiently without increasing board thickness.

Flexible PCBs and Their Advantages

Wearables often benefit from flexible printed circuit boards (FPCBs) due to their ability to conform to curved surfaces or fold within tight enclosures. Key benefits include:

- Mechanical Flexibility: FPCBs enable integration into fabric, wristbands, or other flexible accessories, enhancing ergonomic design.

- Space Savings: Folding or bending flexible circuits reduces the overall device volume by stacking layers without rigid connectors.

- Improved Durability: Flex circuits reduce mechanical stress on solder joints as they flex with the movement of the wearer.

When designing with flexible PCBs, consider careful strain relief at bend points and use flexible-compatible components and adhesives to maintain long-term reliability under repetitive motion.

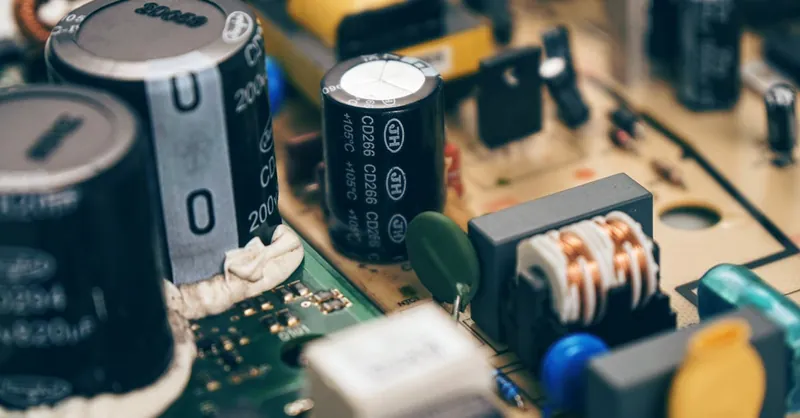

Integrating Power Management Modules

Efficient power management is critical for wearable devices to maximize battery life while ensuring stable operation:

- Low-Dropout (LDO) Regulators and DC-DC Converters: Use high-efficiency buck or boost converters tailored for low current draws. Switching regulators improve battery runtime but can introduce noise; therefore, balancing efficiency and signal integrity is essential.

- Battery Charging ICs: Integrate dedicated charging controllers with protection features for lithium-ion or lithium-polymer batteries, including overcharge, overdischarge, and temperature monitoring.

- Power Path Management: Implement circuitry to seamlessly switch power sources (battery vs. external USB power) without interrupting device operation.

- Energy Harvesting Modules: For advanced wearables, consider integrating solar cells or kinetic energy harvesters coupled with power management ICs to extend operational time.

By combining compact PCB design techniques, flexible circuit options, and sophisticated power management, you create wearable devices that are not only sleek and lightweight but also capable of long, reliable operation with minimal user inconvenience. This holistic approach is key to professional-quality wearable hardware development that meets the demands of modern embedded systems and consumer expectations.

Image courtesy of Pixabay

Power Management Strategies for Wearable Devices

Efficient power management is the cornerstone of successful wearable device design, directly influencing battery life, user convenience, and overall device reliability. Selecting the right battery technology, integrating effective charging circuits, and leveraging advanced software techniques such as sleep modes and dynamic power scaling are vital to maximize operational time while maintaining a compact form factor.

Battery Options for Wearables

Choosing the ideal battery involves balancing energy density, size, weight, safety, and longevity:

-

Lithium-Polymer (Li-Po) Batteries:

Widely used in wearable devices due to their high energy density, flexible form factors, and relatively low weight. Li-Po batteries support custom shapes, ideal for sleek wearable enclosures. However, they require protective circuitry and proper charging management to ensure safety and battery health. -

Lithium-Ion (Li-Ion) Batteries:

Common in larger wearables; offer high capacity and cycle life but are typically rigid and heavier than Li-Po cells. They also necessitate robust charge protection circuits and thermal monitoring. -

Coin Cell Batteries (e.g., CR2032):

Suitable for ultra-low-power devices with minimal energy demands. Coin cells offer very compact size and convenience but have limited capacity and cannot be recharged. -

Alternative Options:

Emerging technologies like flexible thin-film batteries or supercapacitors offer promising form factor advantages but often trade off capacity or require specialized charging approaches.

Designing Charging Circuits

Integrating a reliable charging system ensures user-friendly operation and battery longevity:

- Use dedicated battery charging ICs designed for the selected battery chemistry, often including features like overcharge protection, temperature sensing, and charge current regulation.

- Prefer USB-based charging circuits with integrated power path management, enabling seamless device operation during charging without power interruptions.

- Consider adding wireless charging coils (Qi standard or similar) for enhanced user convenience in premium wearable designs.

Software Techniques to Maximize Battery Life

Optimizing firmware to reduce power consumption is equally important:

- Implement Sleep and Deep Sleep Modes: Most modern MCUs support multiple low-power states where clocks and peripherals are halted or slowed, drastically reducing current draw during inactivity.

- Use Interrupt-Driven Design: Avoid continuous polling of sensors or inputs; instead, trigger processing only upon events to minimize active runtime.

- Dynamic Frequency and Voltage Scaling (DVFS): Adjust the MCU’s clock speed and supply voltage according to workload demands to optimize energy use without compromising performance.

- Efficient Sensor Sampling: Schedule sensor readings and wireless transmissions in bursts and batches, reducing the power cost of communication and peripheral operation.

- Power Profiling and Monitoring: Utilize onboard ADCs or dedicated fuel gauge ICs to monitor battery voltage and current, allowing adaptive power management strategies in software.

By combining careful battery selection, robust charging circuit integration, and intelligent software power-saving techniques, you can significantly extend the runtime of wearable devices, enhance user experience, and reduce maintenance hassle. Power management is not an afterthought but a foundational element in crafting high-performance, reliable wearables that meet the demands of modern users and embedded systems developers alike.

Image courtesy of Francesco Paggiaro

Programming Wearables in Python and C/C++

When it comes to developing firmware for wearable devices, choosing the right programming language and development environment can significantly affect both your productivity and the device's performance. Two dominant languages for wearable microcontroller development are Python (in the form of MicroPython or CircuitPython) and native C/C++. Each has distinct advantages and considerations, especially when targeting resource-constrained, power-sensitive wearable platforms.

Python for Wearable Firmware: MicroPython and CircuitPython

Python variants tailored for embedded devices, such as MicroPython and CircuitPython, offer an accessible and fast development cycle, ideal for rapid prototyping and iterative design. They bring benefits such as:

- Ease of use: Python’s high-level syntax and vast ecosystem of libraries accelerate development for sensor integration, data processing, and communication protocols.

- Interactive REPL: Real-time code testing and debugging via serial console or USB enable quick experimentation and firmware updates without full recompilation.

- Portability: Python scripts often require minimal changes when migrating between various MCUs and boards, thanks to hardware abstraction layers.

- Rich community support: Extensive examples and tutorials for common sensor modules and wearable libraries simplify project development.

However, Python firmware typically incurs additional overhead in RAM and flash usage and can result in somewhat slower execution compared to compiled C/C++. This may impact battery life and real-time responsiveness in high-demand applications like continuous sensor fusion or signal filtering.

Common development environments for MicroPython/CircuitPython include:

- Thonny IDE: Popular for CircuitPython, providing an intuitive interface for code editing, device file management, and serial monitoring.

- VS Code with Pymakr extension: Enables advanced code editing, flashing, and interactive debugging for MicroPython devices.

- Command-line tools:

ampyandrshellfor file management and firmware flashing on embedded devices.

Native C/C++ for Wearable Development

Using C/C++ for native firmware remains the industry standard for performance-critical, production-grade wearable devices. Advantages include:

- Maximum efficiency: Compiled C/C++ code runs faster and consumes less memory, crucial for low-power operation and real-time sensor data processing.

- Fine-grained hardware control: Direct register manipulation and peripheral configuration allow precise tuning of low-power modes, interrupts, and communication protocols.

- Comprehensive SDKs and HALs: MCU vendors provide optimized libraries and development frameworks (e.g., STM32Cube, Nordic’s nRF SDK, ESP-IDF) that simplify peripheral setup and power management.

- Robust debugging: Access to hardware debuggers (JTAG/SWD) enables breakpoint setting, variable inspection, and step-through execution, critical for diagnosing complex behavior in embedded wearables.

Key C/C++ development environments include:

- PlatformIO: An extensible ecosystem supporting numerous MCUs with integrated build, debug, and version control features inside Visual Studio Code.

- Segger Embedded Studio and Keil MDK: Professional-grade IDEs with advanced debugging and profiling tools tailored for ARM Cortex MCUs.

- Arduino IDE: While less powerful for large-scale projects, Arduino supports C/C++ development for many wearable-friendly boards like ESP32 and RP2040.

Debugging Tips for Wearable Firmware Development

Regardless of the chosen language, debugging embedded wearables can be challenging due to limited interfaces and real-time constraints. Here are effective debugging strategies:

- Use Serial Logging Judiciously: Insert well-placed debug prints to trace execution flow and sensor values, but disable or optimize logs in production to save power and processing cycles.

- Leverage Hardware Debuggers: Connect SWD or JTAG interfaces to halt code execution, inspect registers, and step through critical code segments without intrusive logging.

- Employ Unit Testing and Simulation: Develop firmware modularly to allow isolated testing of algorithms and drivers on host machines before deploying to devices.

- Monitor Power Consumption: Use power analyzers or built-in MCU tools to correlate code execution with energy usage, identifying code paths that can be optimized for sleep time or reduced processing.

- Implement Watchdog Timers and Fault Handlers: Ensure firmware robustness by handling unexpected conditions and automating recovery to improve reliability of wearable devices.

Summary of Python vs. C/C++ in Wearable Firmware

| Aspect | Python (MicroPython/CircuitPython) | C/C++ (Native Firmware) |

|---|---|---|

| Development speed | Fast prototyping and iteration | Longer setup but optimized performance |

| Memory and CPU usage | Higher overhead, less efficient | Highly efficient and low footprint |

| Hardware control | Abstracted, less control over registers | Direct control for peripherals and power modes |

| Debugging | REPL and serial output, limited hardware debugging | Full hardware debugging support |

| Community & Libraries | Growing embedded Python ecosystem | Mature SDKs and broad MCU vendor support |

| Suitability for wearables | Ideal for prototypes and less demanding apps | Best for production, real-time, power-sensitive devices |

Choosing between Python and C/C++ ultimately depends on your wearable project's complexity, power constraints, time-to-market, and your familiarity with embedded tools. Python accelerates learning and development cycles, making it perfect for hobbyists and rapid prototyping. C/C++ provides the performance and precise control necessary for long-lasting, feature-rich commercial-grade wearables.

By understanding these trade-offs and leveraging the best tools and debugging practices for each language, you can build efficient, reliable, and innovative wearable devices tailored to your unique application and user needs.

Image courtesy of ThisIsEngineering

Implementing Wireless Connectivity in Wearable Devices

Incorporating wireless communication protocols is essential for modern wearable devices to enable seamless data transfer, remote monitoring, and Internet of Things (IoT) integration. Choosing the right connectivity technology—be it Bluetooth Low Energy (BLE), Wi-Fi, or Near Field Communication (NFC)—depends on your wearable’s power budget, data throughput needs, range requirements, and target user experience. Understanding how to efficiently integrate these protocols into microcontroller-based wearables will elevate your device’s functionality and interoperability within the expanding IoT ecosystem.

Bluetooth Low Energy (BLE)

BLE is the most prevalent wireless standard for wearables due to its ultra-low power consumption, reliable short-range communication, and widespread compatibility with smartphones and tablets. BLE enables real-time streaming of sensor data such as heart rate, activity patterns, or environmental conditions with minimal impact on battery life. Many ARM Cortex-M microcontrollers and modules, including Nordic Semiconductor’s nRF52 series and ESP32, offer integrated BLE stacks and hardware accelerators that simplify development.

Key aspects of BLE integration for wearables include:

- GATT Profile Implementation: Define services and characteristics that represent the wearable’s data points, enabling structured communication and easy smartphone app development.

- Efficient Advertising and Connection Intervals: Optimize advertising intervals and connection parameters to balance responsiveness with power savings.

- Security Features: Implement pairing and bonding protocols to secure sensitive health or personal data transmitted via BLE.

- Cross-Platform Support: Leverage libraries such as BlueZ (Linux), CoreBluetooth (iOS), or Android BLE APIs to ensure seamless connectivity with common mobile platforms.

Wi-Fi Connectivity

While more power-hungry than BLE, Wi-Fi integration suits wearables that require higher data rates, long-range connectivity, or direct cloud communication without intermediate gateways. Devices like the ESP32 combine Wi-Fi and BLE, providing flexible wireless options. Wi-Fi enables continuous data streaming, firmware over-the-air (OTA) updates, and advanced IoT interactions.

When integrating Wi-Fi into wearables, consider:

- Power Management: Use sleep modes and optimized transmit power settings to conserve battery life.

- Network Configuration: Employ smart provisioning techniques such as Wi-Fi Easy Connect or captive portals for user-friendly setup.

- Data Security: Utilize strong encryption (e.g., WPA3) and secure transmission protocols like MQTT over TLS to protect user data.

- OTA Firmware Updates: Implement secure and reliable OTA mechanisms for firmware maintenance and feature enhancements.

Near Field Communication (NFC)

NFC offers a short-range, low-power communication method ideal for quick device pairing, secure authentication, or contactless payments within wearables. NFC requires minimal power, often harvesting energy from the reader device, making it an excellent complement to BLE in wearable ecosystems.

NFC integration considerations include:

- Tag Emulation and Reader Modes: Implement supported NFC modes to enable interactions like device unlocking or data exchange with smartphones or terminals.

- Simplified Pairing: Use NFC to initiate BLE pairing, reducing user friction in device setup.

- Data Limitations: Account for NFC’s small payload size and low data rate by offloading extensive data transfer to BLE or Wi-Fi.

Integrating Communication Protocols into Wearable Firmware

Building efficient firmware that manages wireless communication involves:

- Modular Wireless Stacks: Use vendor-provided or open-source protocol stacks tailored for your MCU to streamline implementation and power optimization.

- Event-Driven Architecture: Schedule radio activities around sensor sampling and processing to minimize radio-on time and conserve energy.

- Buffer Management: Implement circular buffers and timestamped packets to handle asynchronous incoming/outgoing data gracefully.

- Error Handling and Reconnections: Ensure robust recovery mechanisms for packet loss, signal interference, and connection drops.

By mastering the use of BLE, Wi-Fi, and NFC communication protocols along with smart integration in embedded firmware, you can transform simple wearable gadgets into intelligent, connected devices that communicate effortlessly with smartphones, cloud platforms, and other IoT nodes—driving innovation in health, fitness, and smart lifestyle applications.

Image courtesy of Shotkit

Developing Firmware for Reliable and Responsive Performance

Creating firmware that delivers reliable and responsive performance is essential for wearable devices where real-time data acquisition, sensor fusion, and event-driven programming form the backbone of accurate monitoring and seamless user experience. In the context of embedded systems for wearables, adopting best practices ensures your device processes sensor inputs efficiently, responds promptly to events, and conserves power without compromising functionality.

Real-Time Data Acquisition

For wearables that continuously monitor physiological signals, motion, or environmental variables, real-time data acquisition demands precise timing and minimal latency. Key strategies include:

- Utilizing Hardware Timers and Interrupts: Leverage microcontroller timers and interrupts for periodic sensor reads instead of relying on processor-intensive polling loops. This ensures consistent sampling intervals critical for signal integrity.

- Buffering and DMA (Direct Memory Access): Employ DMA to transfer sensor data directly to memory buffers, reducing CPU load and enabling uninterrupted data flow—vital for high-frequency sensors like accelerometers or PPG modules.

- Precision Timestamping: Implement accurate time-stamping of samples using real-time clocks (RTC) or timer counts to align data streams and support time-series analysis or synchronization with external devices.

Sensor Fusion for Enhanced Accuracy

Sensor fusion combines data from multiple sensors (e.g., accelerometer, gyroscope, magnetometer) to improve the accuracy and reliability of motion tracking, orientation detection, or health monitoring in wearables. Effective sensor fusion techniques involve:

- Complementary and Kalman Filters: Integrate these algorithms in firmware to smooth noisy data, compensate for sensor drift, and produce stable, reliable outputs.

- Data Normalization and Calibration: Regularly calibrate sensors and normalize incoming data to account for variations due to device placement, temperature, or manufacturing tolerances.

- Modular Fusion Pipelines: Architect the firmware with modular sensor fusion components that can be individually tuned or replaced, aiding maintainability and scalability.

Event-Driven Programming for Power Efficiency and Responsiveness

Adopting an event-driven programming model is fundamental to balancing responsiveness with power conservation in wearables:

- Interrupt-Triggered Processing: Use hardware interrupts to wake the MCU only when relevant sensor thresholds are crossed or user inputs occur, reducing unnecessary CPU active time.

- Finite State Machines (FSMs): Structure firmware logic as FSMs to systematically manage device states (e.g., idle, sampling, transmitting) and transitions triggered by events.

- Asynchronous Task Handling: Implement lightweight task schedulers or real-time operating systems (RTOS) to manage concurrent operations like sensor reading, wireless communication, and user interface handling without blocking critical activities.

- Debouncing and Event Filtering: Incorporate debouncing logic and event filtering to minimize false triggers from noisy sensor inputs or rapid state changes.

By embedding these best practices in your wearable firmware development, you ensure your device operates with high accuracy, reliability, and responsiveness while optimizing power consumption—critical for creating innovative, user-friendly wearable technology that stands out in today’s competitive market of embedded systems and microcontroller projects.

Image courtesy of Tuğçe Açıkyürek

Testing, Calibration, and User Interaction in Wearable Devices

Ensuring sensor accuracy and device reliability through rigorous testing and calibration is fundamental to the success of any wearable project. Because wearable devices often operate in dynamic, real-world environments, sensor readings can be affected by factors like temperature variations, motion artifacts, or hardware drift. Implementing systematic calibration procedures and thoughtful user interaction design guarantees precise data capture and smooth usability, ultimately enhancing user satisfaction and trust.

Strategies for Testing and Calibrating Wearable Sensors

-

Baseline Calibration:

Begin by establishing baseline measurements for sensors under controlled conditions. For example, zero acceleration calibration for IMUs or known temperature references for thermistors. This step corrects offset errors and sensor bias inherent to hardware. -

Dynamic Calibration and Recalibration:

Since wearable sensors are subject to changing environmental conditions and usage patterns, implement software routines that allow periodic or on-demand recalibration. Techniques include sensor fusion algorithms that compensate for drift, or user-guided calibration steps during device setup. -

Cross-Validation with Reference Devices:

Conduct thorough testing by comparing sensor outputs against trusted reference instruments (e.g., medical-grade pulse oximeters or lab accelerometers). This external validation helps identify systematic errors and refine firmware algorithms accordingly. -

Automated Test Harnesses and Simulation:

Use hardware-in-the-loop (HIL) simulators or scripted test sequences to evaluate sensor response across anticipated ranges and scenarios. Automated tests reduce human error, speed up development, and provide repeatable, quantifiable results. -

Environmental Stress Testing:

Expose devices to temperature cycles, humidity, and mechanical stress to evaluate sensor stability and durability. This ensures long-term reliability and user confidence in various usage conditions.

Designing Intuitive User Interfaces for Wearables

An effective wearable device not only gathers accurate data but also offers an intuitive and engaging user interface (UI) that facilitates effortless interaction despite limited display sizes and input options. Consider these best practices:

- Minimalist Display Elements: Use clear icons, concise text, and high-contrast visuals to convey essential information quickly, accommodating glance-based and low-light usage typical of wearables.

- Haptic Feedback and Audio Cues: Incorporate vibration motors or simple sound notifications to confirm user actions, alerts, or mode changes without relying solely on visual feedback.

- Gesture and Touch Controls: Implement user input methods tailored to small form factors, such as capacitive touch buttons, swipe gestures, or tap sequences, enabling natural and unobtrusive control.

- Customization and Accessibility: Allow users to adjust settings like display brightness, notification types, and measurement intervals through companion smartphone apps or on-device menus, enhancing personalization and comfort.

- Consistent Interaction Flow: Design UI workflows that minimize cognitive load by providing predictable, easily navigable menus and clearly indicated system states (e.g., battery status, connectivity).

By marrying precise sensor calibration with thoughtfully designed user interfaces, you create wearable devices that deliver accurate, actionable insights while maintaining seamless and satisfying user experiences. These elements are critical in building trustworthy, user-centric wearables that excel in both performance and engagement.

Image courtesy of Tuğçe Açıkyürek

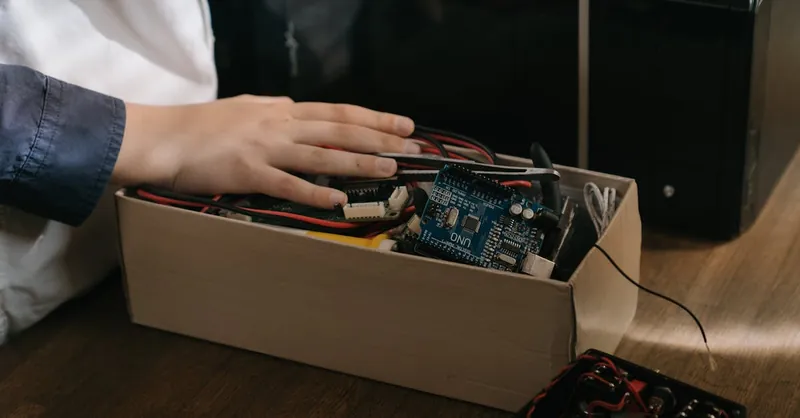

Popular Wearable Projects and Open Source Resources

Jumpstarting your journey into wearable device development becomes much easier and more inspiring when you explore popular wearable projects and leverage open-source resources. These projects not only demonstrate practical applications of microcontrollers like Raspberry Pi, ARM Cortex MCUs, and ESP32 but also provide reusable software libraries, hardware designs, and supportive communities that accelerate your learning curve and innovation potential.

Inspiring Example Wearable Projects

-

DIY Fitness Trackers and Smartwatches:

Numerous open-source projects like the AstroWatch or Wristify showcase custom-designed fitness trackers that monitor heart rate, steps, and sleep using ARM Cortex-M microcontrollers paired with BLE modules. These projects often provide complete schematics, firmware code in C/C++ or MicroPython, and companion smartphone apps, offering a practical blueprint for building your own health-monitoring wearable. -

Wearable Air Quality and Environmental Monitors:

Projects integrating compact gas sensors, temperature, and humidity sensors with microcontrollers like the Raspberry Pi Pico or ESP32 demonstrate how to create portable environmental wearables. These devices send live data via Wi-Fi or BLE to cloud platforms for advanced analytics, highlighting the potential for IoT-enabled health and safety wearables. -

Smart Clothing and Gesture-Control Devices:

Open projects using flexible PCBs and accelerometer sensor fusion implement gesture recognition for controlling music players or smart home devices. These innovative wearables combine embedded systems programming and compact hardware design, providing excellent learning opportunities for integrating sensors and wireless communication in constrained form factors. -

Medical Monitoring Devices:

From open-source pulse oximeters to ECG monitors, the maker community offers projects that apply PPG and bio-signal sensors with ARM Cortex MCUs to deliver clinical-grade data. These projects often include detailed calibration procedures and firmware optimized for real-time data acquisition and power efficiency.

Valuable Open Source Software Libraries and Tools

-

FreeRTOS and Zephyr RTOS:

These real-time operating systems provide a robust framework for multitasking, sensor management, and power optimization in wearable firmware, widely supported across ARM Cortex and ESP32 platforms. -

Bluetooth Low Energy (BLE) Stacks:

Nordic Semiconductor’s SoftDevice, Espressif’s ESP-IDF BLE libraries, and BlueZ on Linux offer modular, optimized BLE protocol implementations crucial for seamless wireless integration in wearables. -

Sensor Driver Libraries:

Open-source drivers on GitHub for common wearable sensors like the MAX30102 heart rate sensor or MPU-9250 IMU enable quick integration and reduce development time, compatible with C/C++ and MicroPython environments. -

Data Visualization and Analytics Tools:

Platforms like ThingSpeak, Grafana, and Blynk facilitate remote monitoring and interactive dashboards for wearable sensor data, connecting embedded devices to user-friendly interfaces via MQTT or HTTP APIs.

Engaged Communities and Learning Platforms

-

Hackster.io and Instructables:

These platforms host extensive wearable project tutorials, schematics, and source code contributed by global makers and professionals, perfect for inspiration and step-by-step guidance. -

Raspberry Pi and Arduino Forums:

Official and third-party forums are vibrant hubs where developers share code snippets, troubleshoot hardware issues, and exchange best practices related to wearable microcontroller development. -

GitHub Repositories and Open Hardware Initiatives:

Many wearable projects maintain active repositories that encourage collaboration and improvements, enabling you to contribute, customize, or fork existing designs to suit your unique needs.

By exploring these popular wearable projects and tapping into open-source software libraries, development tools, and active communities, you gain a wealth of practical knowledge and ready-to-use resources. This combination empowers you to design, program, and build innovative wearable devices—from initial prototypes to polished products—while fostering continuous learning and connection within the embedded systems and maker ecosystems.

Image courtesy of cottonbro studio